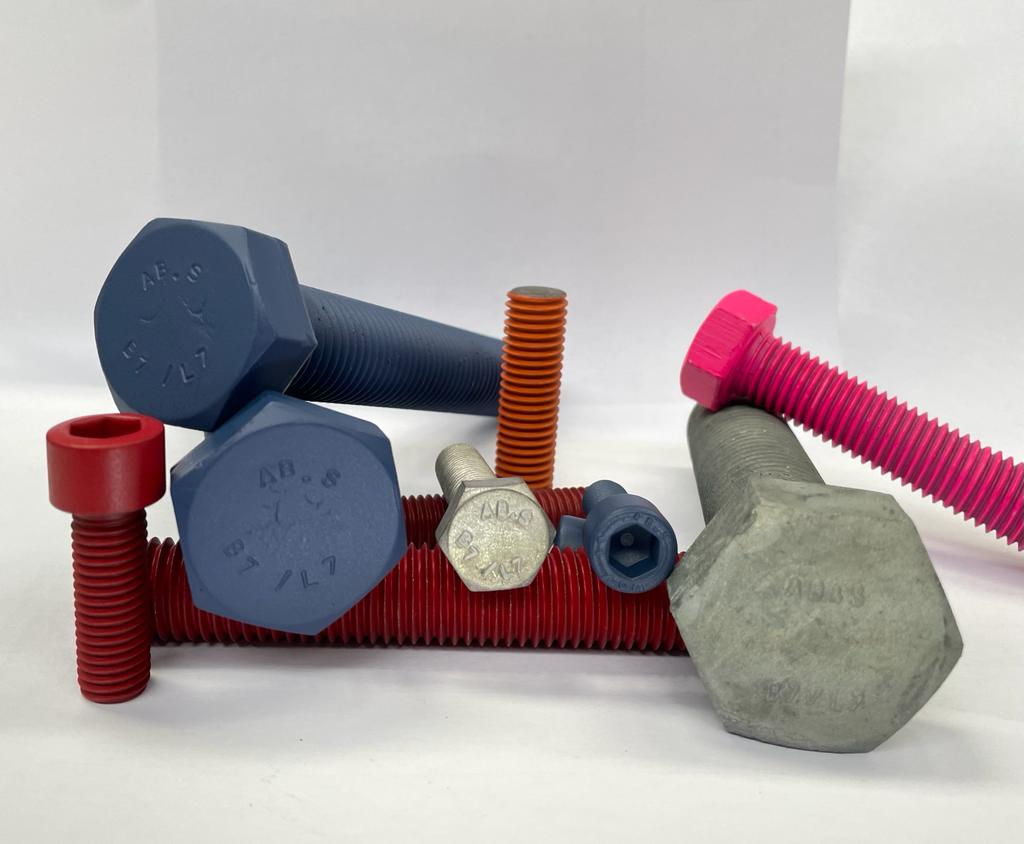

MATERIALS

Our company specializes in the outsourcing of steels and special alloys, providing tailor-made solutions for a wide range of industrial sectors. We are able to process different types of materials, selected to offer superior performance even in particularly harsh working conditions. Thanks to our consolidated experience and advanced technologies, we are able to meet the needs of the most demanding customers, guaranteeing high quality components that last over time.

Customized Processing of our materials for Every Need

Our ability to work with special steels and alloys allows us to offer customized solutions based on the specific needs of the customer. Whether it is heat treatments, mechanical processing or surface finishes, we guarantee that every phase of the production process meets the highest standards, ensuring components of the highest quality.

We work with a wide range of industries, including oil, energy, chemical, automotive, aerospace and more, ensuring maximum reliability and performance every time.

Our experience allows us to provide cutting-edge solutions for every industrial need. We are ready to offer strong, durable and high-performance materials that are ideal for applications that require superior quality. If you need customized solutions for your project, please feel free to request an offer. We are ready to collaborate to find the best solution for your company.

STEELS

UNI EN ISO 3506 GR. A2/A4CL. 50/70/80

ASTM/ASME SA 193 - 320 GR. B8/B8M CL. 1/CL.2/B8A/B8MA

ASTM/ASME SA 194 GR. 8/8A/8M/8MA

UNS S30400 - UNS S31600

ASTM A193 GR. B8T /AISI321) - ASTM A194 GR. 8T

EN 10269: 1.7225 - 1.7218 - 1.7709 - 1.1191

ASTM A193 GR. B8R - XM19 - UNS S20910 Nitronic 50

F53 - UNS S32750 - 1.4410

F55 - UNS S32760 - 1.4501

UNI EN ISO 898-2: CL .8/CL. 10

UNI EN ISO 898-3: 22H/45 H

ACCIAIO 100HV/200HV/300HV - C67 - C72

ASTM/ASME SA 193 GR. B7/B7M/B16

ASTM/ASME SA 320 GR. L7/L7M/L43

ASTM/ASME SA 194 GR. 2H/2HM/4/7/7M

EN 10269: 1.7225 - 1.7218 - 1.7709 - 1.1191

UNI EN 10083-3: 39NiCrMo3

UNI EN 10025-2 - S235 - S275 - S355

EN 10269 1.4980

ASTM A437 GR. B4B

AISI 420 - X30Cr13

ALLOYS

UNS N10276 (ex. HASTELLOY C276 ®)

UNS N04400 (ex. MONEL 400 ®)

UNS N05500 (ex. MONEL 500 ®)

UNS N06625 (ex. INCONEL 625 ®)

UNS N08020 (ex. NICKELVAC 23®)

ASTM B637 UNS N07718 (ex. INCONEL 718 ®)

UNS R50400 TI Gr.2 Ti Gr. 5